Leveraging RFID for Forklifts

Why we need a smart logistics system that includes RFID with forklifts.

As the use of wireless communication grows across industries, radio frequency identification (RFID) becomes one of the best ways to improve accuracy and efficiency in material-handling. There has been a greater use of RFID in warehouses to promote a smart logistics system. Leveraging RFID for forklifts is one of the best practices that promises great benefits.

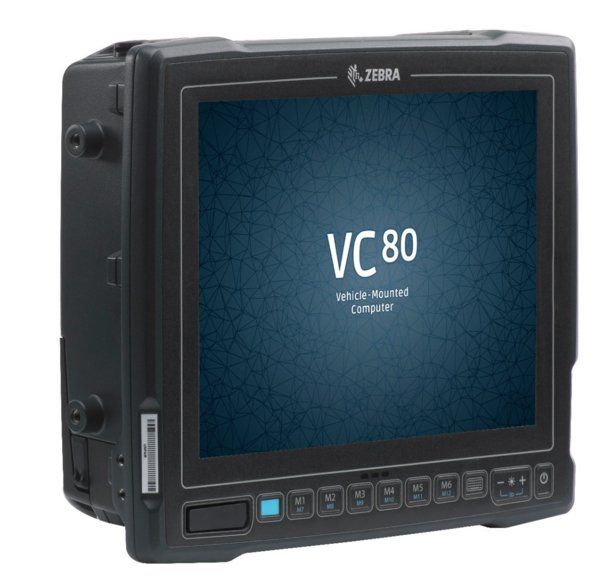

Forklifts are widely used in warehouses for material-handling, shipping, and other operations. RFID-mounted forklifts are deployed in warehouses IT systems to enable fast and effective communication with managers, assistants, and operational directors. To incorporate this system, developments in architectural components and system upgrades are necessary.

Functions of RFID-Mounted Forklifts

Forklifts are one of the most expensive equipment used in warehouses. They are heavy and can pose great safety risks if the personnel is not trained or equipped with safety gear. This is why RFID is being used as a cost-effective solution to handle these heavy machines efficiently and reduce mishandling. RFID ensures user authentication and access control systems when using forklifts.

User authentication is when warehouse managers can identify and ensure that personnel with relevant training and authorization are handling the machine. RFID helps in smart authorization of these individuals. Meanwhile, access control systems are to ensure that only authorized users get access to the forklifts’ operations.

This is done through mounting forklifts with an RFID tag and assigning all employees an RFID tag. The RFID of the employee and the forklift will match if the employee is authorized. If any unauthorized access is observed, the RFID will send signals and notifications to the manager.

Benefits of Leveraging RFID for Forklifts

Up to 60% of all warehouse accidents are due to the mishandling of forklifts by untrained or unauthorized people. The RFID technology for forklifts will ensure safety, security, and lower risks of damage. It will prevent not only accidents and risks of injuries but also any costly damage to goods due to mishandling or incompetent infrastructure. The following are the benefits of RFID for forklifts.

1. Smart Logistics System

Using RFID for forklifts is a step ahead to create a smart logistics system where costs of damage and risks of accidents are reduced. Logistics and operational managers can keep track of employee identities and authorized entries while sitting in their offices.

2. Easy Record System

Using RFID technology in warehouses can help keep statistical records in a more efficient manner as all the data will be saved automatically. The RFID-mounted forklifts can track all material-handling, making it easier for managers to maintain inventories and track damage.

3. Enhance Facility Productivity

By using RFID for forklifts, managers can track employee activity at the warehouse in a more efficient manner and prepare safety statistics. This will enhance overall warehouse facility productivity with reduced waste or damage.

RFID technology can make your warehouses safer and more accessible. Every logistics company should consider a smarter system to improve efficiency and reduce costs.

Talk to one of our Printer & Barcode Technology Specialists about all RFID solutions in the warehouse. Call today (800) 643-2664 .

Related Links:

https://www.midcomservicegroup.com/zebra-vc80-vehicle-computer

https://www.midcomservicegroup.com/onsite-printer-repair

https://www.midcomservicegroup.com/express-repair-centers

https://www.midcomservicegroup.com/how-to-eliminate-picking-problems-at-the-warehouse

https://www.midcomservicegroup.com/sap-and-thermal-rfid-printer-improve-productivity

https://www.midcomservicegroup.com/how-is-rfid-changing-real-world-applications