15 Zebra Printer Maintenance Tips That Are Easy To Do

Control your Zebra! Use these easy to do maintenance tips.

Are your Zebra printers

controlling you? Wouldn't you like to control them? Here are 15 Zebra printer maintenance

tips that will help you ride high.

Zebra Printer Maintenance Tip #1

One of the

greatest failures occurring in thermal barcode printers

is due to the printheads

not being cleaned regularly.

A good rule of thumb is to clean the printhead

on each of your Zebra thermal

printers

every time you replace a ribbon or roll of paper. It takes only about

a minute and this action could save you thousands of dollars over the life of

the printer.

Follow the instructions in your User’s Manual as to the type of cleaning solvent

to be used for your specific model.

Zebra Printer Maintenance Tip #2

If you feel you are burning out printheads

too often

on your Zebra printer

, you may want to check your User’s Manual for the

recommended heat and darkness settings. An incorrect setting often will reduce

the printhead

life and could cost you thousands of dollars over the life of the

printer.

Zebra Printer Maintenance Tip #3

Dust residing on the Media Sensor can cause major service issues. The Media Sensor is the mechanism that insures that the gap between the paper and the printhead remains constant.

Most people purchase a bottle of "canned air" and simply give the Media Sensor a few quick blasts of air, which will usually clear out any dust residue left over from the roll paper. You should consider doing this regularly, every time you change the ribbon or a roll of paper. It will only take a few seconds and it will ensure more up-time.

Zebra Printer Maintenance Tip #4If you are using a ribbon in your Zebra thermal printer , be sure that it is a good quality ribbon. Lower cost ribbons are often not manufactured to the exact wax and/or resin specifications of your printer and could cause a wax build-up on the platen.

Wax build-up can cause poor print quality resulting in barcode reliability issues.

Zebra Printer Maintenance Tip #5If you are using a Zebra thermal printer that does not use a ribbon (typically called a Direct Thermal printer vs. a Thermal Transfer printer that does use ribbons) and you are constantly having problems with defective printheads , you may want to consider either changing your printer to a Thermal Transfer printer or using a better quality paper.

A Thermal Transfer printer

, due to the position of the ribbon

between the printhead

and the label paper

, can greatly extend the life of thermal printheads

,

as paper is not directly rubbing against the printhead

itself and causing

friction.

Zebra Printer Maintenance Tip #6

A good rule of thumb, when purchasing new ribbons

on thermal transfer printers

, is to purchase a ribbon

that is slightly

wider than the actual labels

that you are using. For instance, if the label

that you are using is 4.1" in width, then you may want to consider

purchasing ribbons

that are 4.33" in width.

This extra width will help keep more lubrication on the printhead

and help

extend printhead

life.

Zebra Printer Maintenance Tip #7

Are you wearing out printheads

? If so, here is something you

may want to check.

Be sure that you are

not

using low grade label

paper if you are

using Direct Thermal printers. Often bargain priced rolls of paper really are

not a "bargain".

Why?

Because low grade paper often is coarser and can cause more wear on the printheads. We have seen situations with even as high as 50% more wear on the printhead. As you may know, printheads in thermal printers are very expensive.

It may make sense to pay a little more for paper, as it is a fraction of the cost compared to replacing printheads more often.

Remember, the manufacturers of thermal printers consider the printheads as consumables that the end-user is responsible to replace. These consumables run into the hundreds of dollars each.

Zebra Printer Maintenance Tip #8Have burned-out printhead elements on your Zebra printer ? Here is how to tell with a PAUSE TEST.

There may be situations where it looks like information is missing on your labels and/or barcodes when they are being printed. There is always a chance that one or more of the print elements in your Zebra printer printhead may be burned out.

Before calling someone for a Zebra printer repair , you may want to try this simple test that only takes a few moments to see if in fact it is your print elements. Keep in mind that Zebra considers printheads as consumables and they must be replaced from time to time. Typically this is performed by a qualified printer repair technician.

This self test can be used to print test labels when you make adjustments to the Zebra printer's mechanical assemblies to determine if any of the printhead elements are not working.

Complete these steps to run the Pause Test:

1. Turn the Zebra printer off.

2. Press and hold the Pause key while turning the printer on. Hold the Pause key until the first control panel light turns off.

- The initial test pattern will start printing 15 labels at the Zebra printer's slowest speed, and then it will automatically pause the printer. Each time the Pause key is pressed, the Zebra printer will print another 15 labels.

- While the printer is paused, pressing the Cancel alters the self test. Each time the Pause key is pressed, 15 labels print at 6 inches per second.

- While the printer is paused, pressing the Cancel again alters the self test a second time. Each time the Pause key is pressed, 50 labels are printed at the Zebra printer's slowest speed.

- While the printer is paused, pressing the Cancel again alters the self test a third time. Each time the Pause key is pressed, 50 labels are printed at the 6 inches per second.

- While the printer is paused, pressing the Cancel again alters the self test a fourth time. Each time the Pause key is pressed, the printer will print 15 labels at the printer's maximum speed.

3. To exit the self test at any time, press and hold Cancel.

The actual Pause Test label

will indicate on it

if one of the print elements on the printhead

is defective as part of the test

pattern. Part of the test pattern printed is total black, and if there is a

defective printhead

, this portion of the test label

will indicate white spots.

This indicates that there is a bad print element and the printhead

will need

replacing. At this point you may need to call a printer repair company.

A good printer repair company

sees this issue often and will be able to supply

you with a new Zebra printhead

and will also fully check out your Zebra

printer. A steady program that includes Zebra printer maintenance

will help you

keep your printer up and running longer.

What are

printer and print server alerts? Should you pay attention to them?

Alerts give you the ability to proactively manage your Zebra printer

and print

server. If the printer or print server has an error, you would be sent an alert

notifying you of the situation. ZebraNet Bridge gives you control to monitor

your bar code printers from anywhere, and documents the alerts to a log file.

A soon as ZebraNet Bridge receives an alert, the alert appears in the Events tab. If you have not viewed the alert yet in the Events tab, the box in the status bar at the bottom of the application shows:

- New alert

- Alert type

- Alert severity by color

You can configure ZebraNet Bridge to notify you by blinking the application tab in the task bar. Remember, ZebraNet Bridge only logs alerts that occur while the application is running.

A good Zebra repair company sees this issue often and will be able to supply you with a new Zebra printhead and will also fully check out your Zebra printer. A steady program that includes Zebra printer maintenance will help you keep your printer up and running longer. Zebra Printer Maintenance Tip #10

Clean the exterior and interior area of your Zebra printer often.

To keep your Zebra printer running optimally, remember to clean the interior and exterior of the printer. When these areas are dirty, the chance of debris getting into the wrong area is increased.

To clean the exterior surfaces of the printer use a lint-free cloth. Do not use harsh or abrasive cleaning agents or solvents. If necessary, a mild detergent solution or desktop cleaner may be used sparingly.

You should inspect the interior area after every four rolls of media. Remove any dirt and lint from the interior of the printer using a soft bristle brush and/or vacuum cleaner.

A good Zebra repair company sees this issue often and will be able to supply you with a new Zebra printhead and will also fully check out your Zebra printer. A steady program that includes Zebra printer maintenance will help you keep your printer up and running longer.

Zebra Printer Maintenance Tip #11Don't forget to clean the Printhead and Platen Roller!

To keep your Zebra printer running at its optimum it is a good rule of thumb to clean it regularly. If you recognize inconsistent print quality, such as voids in the bar code or graphics, this may indicate a dirty printhead. For best results, perform the following cleaning procedure after every roll of ribbon.

Note: You do not need to turn off the printer before cleaning the printhead. If the power is turned off, all label formats and images, as well as any temporarily saved parameter settings stored in the printer's internal memory, are lost. When the power is turned back on, you will need to reload these items.

To clean the printhead :

- Open the printhead

- Remove the media and ribbon (if loaded).

- Moisten an applicator tip with solvent and wipe along the print elements from end to end. (The print elements are on the brown strip just behind the chrome strip on the printhead.) Allow a few seconds for the solvent to evaporate.

- Rotate the platen roller and clean thoroughly with solvent and an applicator.

- Brush/vacuum any accumulated paper lint and dust away from the rollers.

- Reload ribbon and/or media, and close the printhead.

A good Zebra repair company sees this issue often and will be able to supply you with a new Zebra printhead and will also fully check out your Zebra printer. A steady program that includes Zebra printer maintenance will help you keep your printer up and running longer.

Zebra Printer Maintenance Tip #12Extend the life of your printhead and reduce consumable costs.

The printhead is the most critical component in your printer, and possibly the most delicate. It is a consumable item just like the brakes on your car, which eventually wears over time. However, with ongoing careful attention and maintenance, you can extend the life of the printhead !

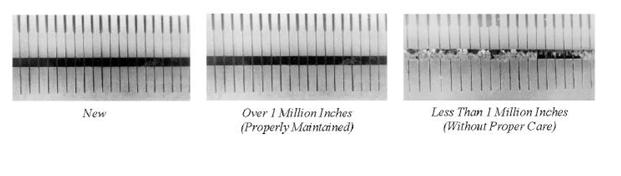

Below are photographs of three printheads. The first printhead is brand new. The second has printed over 1 million linear inches of thermal transfer labels and has been properly maintained. The third printhead has printed far fewer labels , but without proper care and maintenance, signs of abrasion and contamination build-up are evident (see below).

A good Zebra repair company sees this issue often and will be able to supply you with a new Zebra printhead and will also fully check out your Zebra printer. A steady program that includes Zebra printer maintenance will help you keep your printer up and running longer.

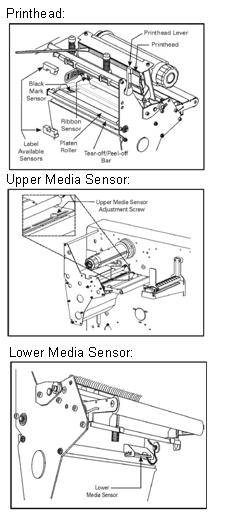

Zebra Printer Maintenance Tip #13Remember to clean the Sensors on your Zebra printers !

The Media, Ribbon and Label Available Sensors should be cleaned on a regular basis to ensure proper operation of your Zebra printer. (To locate these sensors - see diagrams below). Zebra Printer Maintenance Tip #14

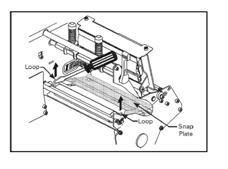

Do you know what the Snap Plate is? You should and it should be regularly cleaned for optimal operation of your Zebra printer.

The Snap Plate should be cleaned to remove label adhesive or a label that has adhered to the underside of the Snap Plate (see below).

- Insert a small-blade screwdriver or similar tool into the loop on the left side of the Snap Plate. Lift the Snap Plate. Caution: Take care not to bend, twist, or otherwise deform the loops!

- Repeat step one on the right side of the Snap Plate.

- Remove the Snap Plate from the printer.

- Clean the Snap Plate with cleaning solvent and a soft cloth.

- To reinstall the Snap Plate, insert the two tabs on the bottom of the Snap Plate into the two slots of the media pathway.

- Slide the Snap Plate toward you.

- Press down on the loops to lock the Snap Plate into place.

Does your Zebra printer have the optional cutter module?

Be sure to clean this to ensure it is working optimally.

If labels are not being cut properly or if the cutter jams with labels , turn off the printer power and unplug the printer. Then, clean the stationary cutter blade with cleaning solvent removing label adhesive and/or paper debris.

For more information on maintaining your Zebra printer and to learn more about your options for all your printer, labeling and barcode printing and scanning needs, call us at (800) 643-2664 and immediately talk to one of our friendly representatives; or chat us up on Facebook , Twitter , Google+ and LinkedIn !

Keep your thermal label printers running! Download our FREE eBook now. click here